At Emanuel Flutes, every instrument begins its journey long before it reaches the hands of a flutist. One of the most remarkable steps in my process is the transformation of raw sterling silver into components that will one day sing in concert halls, opera houses, and studios around the world.

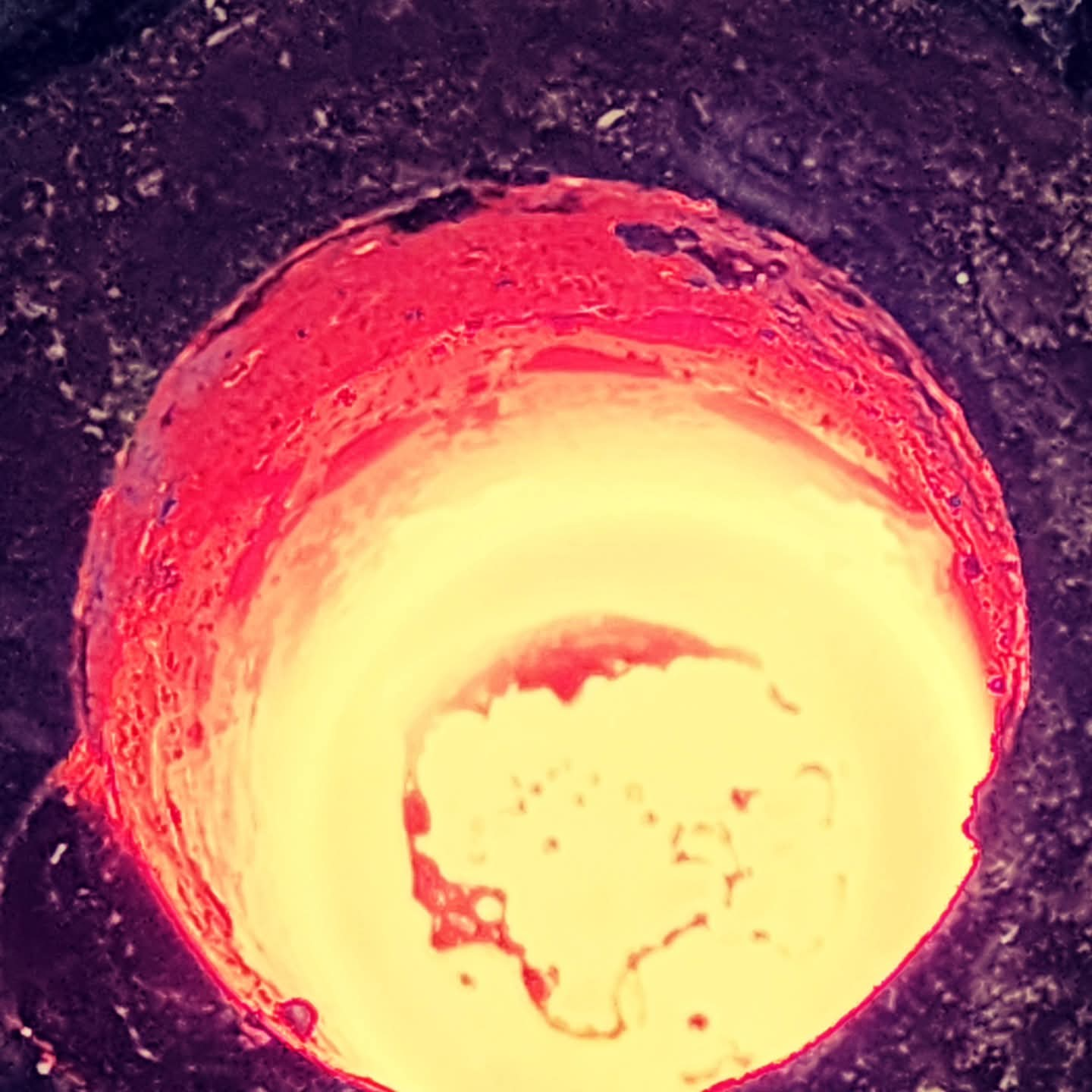

The image above captures a rare glimpse inside my workshop: molten sterling silver, glowing with intense heat, moments before it is poured into the lost wax mold. This ancient casting technique allows me to create parts with exceptional precision and integrity, ensuring both durability and tonal excellence.

Why the Metal Matters

The quality of the metal in a flute is not just about appearance — it is integral to the instrument’s sound, resonance, and response. My choice of premium sterling silver is deliberate, offering a rich, flexible tone that can be shaped by the flutist’s artistry. The purity and consistency of the metal ensure that every Emanuel flute carries the same hallmark of craftsmanship and performance.

The Lost Wax Advantage

Lost wax casting is a method rooted in centuries of metalworking tradition. By using a wax model that is melted away to create a mold, I can achieve unparalleled accuracy in shaping the intricate parts of a flute. This meticulous approach is one of the many reasons my instruments are trusted by top professionals worldwide.

From this glowing crucible of molten silver to the final polished instrument, each Emanuel flute reflects hours of dedicated handcrafting. Every stage — casting, machining, hand-finishing, and final assembly — is guided by my belief that a flute should not only meet the demands of the world’s finest musicians but also inspire them.

In the end, what begins as a pool of molten silver becomes an instrument capable of infinite musical expression. That transformation is the heart of what I do.